Workholding technology

Workholding technology by KIPP

In addition to manufacturing operating and standard parts, KIPP also manufactures workholding technology. The category "workholding technology" includes six product families. The product families include various items and are organised as follows:

- clamping elements

- locating element

- support and stop elements

- form holding systems

- workpiece stabilisers

- chain clamps

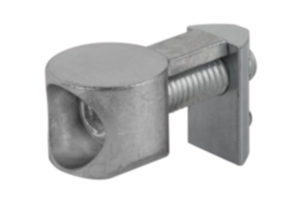

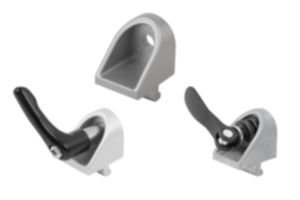

Clamping elements

The product family "clamping elements" includes products such as hook clamps, pull and thrust clamps, clamp straps, clamping units and many more.

With these clamping elements workpieces can be fastened, clamped or retained. Depending on the clamping element, clamping forces bear on the workpiece from the inside, the top or side. Clamping elements can be used in a wide range of application and are used in both one-off and series production.

Clamping elements by KIPP can be divided into two groups:

- mechanical clamping elements

which are operated by manually with the aid of tools.

Mechanical clamping elements include e.g. clamp straps and hook clamps.

- Pneumatic clamping elements

which are not manually operated making them perfect for applications in the automation sector.

In addition to these two groups, clamping elements can also be differentiated by size. The range includes uniform system sizes from M4 - M36, this also covers the main system sizes M6, M8, M10, M12 and M16.

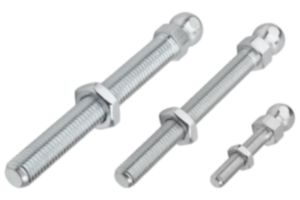

Locating elements

Locating elements are special devices that are used to position workpieces. They are available in various shapes and sizes and are often used in machining industries.

Locating elements can also be used as parts of tool holders or as part of an assembly or testing system. They are able to precisely locate the position of a workpiece and hold it so that it can be used for further work stages.

All products are manufactured to the highest quality standards, are sturdy and durable and can be used in a wide range of applications.

Locating elements are primarily used in sectors such as mechanical engineering, the automotive industry and aerospace.

The KIPP range includes the following locating elements:

- positioning cones

- shoulder screws

- locating bushes

- locating pins

- expanding locating pins

- cylindrical pins

- positioning units

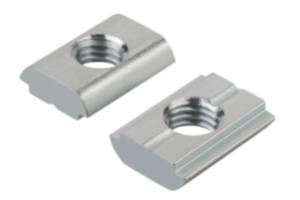

Support and stop elements

Support and stop elements are devices that are used to secure, support or position workpieces on a machine or work table. For this purpose, support and stop elements are attached to the machine or table and serve to support or hold the workpiece in place while it is being processed. They are mainly used for workpiece clamping.

The KIPP range of support and stop elements is unique and offers a wide range of products that can be used for fastening workpieces.

Support elements are usually small devices that are attached directly to the machine, fixture or workplace table to support the workpiece. Support elements are available in various sizes and styles and can be used for a wide range of applications. Some of them can be fitted into collets or jaw plates.

Stop elements are larger elements that are attached to the machine or fixture and determine the position of a workpiece or hold it in place. Stop elements are made of high-quality steel and offer excellent stability when locating workpieces. Stop elements can also be used as a replacement for other positioning aids.

Form holding systems

Form holding systems are a specific type of clamping system used to hold workpieces of certain geometries. They are frequently used in the automotive, aerospace and electronics industries.

Form holding systems consist of a number of components that contribute to holding workpieces with a certain shape. These include:

- collets

- clamping plates

- clamping pins

- and other components

Form holding systems are mainly used in manufacturing industries. They are particularly useful when machining workpieces with complex geometries or uneven surfaces. Form holding systems allow users to position and hold workpieces quickly and precisely.

Kipp uses state-of-the-art technologies to develop and manufacture form holding systems. These are available in various sizes and configurations to meet a wide range of requirements.

Form holding systems offered by KIPP include:

- round and rectangular machinable jaws

- internal and external clamping collets

- mounting plates

- traction cones for internal clamping collets

- pneumatic machinable collet systems

Workpiece stabiliser

Workpiece stabilisers are clamping devices used to stabilise and support workpieces. The workpiece is secured and held rigid by the stabilisers during the machining process. By holding the workpiece rigidly in a specific position, machining can be carried out precisely and efficiently. Workpiece stabilisers are also used for safety and to protect the workpiece and serve as a replacement for clamps.

They are particularly useful when machining workpieces that are difficult to access or handle.

Workpiece stabilisers by KIPP are widely used in the manufacturing industry, including assembly, testing and inspection.

At KIPP, workpiece stabilisers are available in various sizes and forms. The variety of products enables a wide range of applications.

Besides workpiece stabiliser the range also includes the following accessories:

- stabiliser set in a case

- magnets

- extension shafts

- fine adjustments

- fastening sets for T-slots

- fastening sets for zero point clamping technology

- clamp straps

- clamping balls with cup

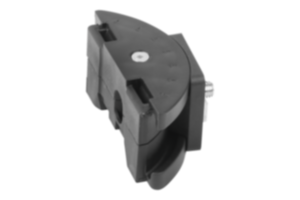

Chain clamps

Chain clamps are a type of mechanical clamping device used to hold, clamp and position workpieces. They consist of a roller chain with a clamping bracket on one end and a clamping hook the other. The bracket and the hook are secured to a table or plate using cap screws. A knurled nut on the bracket is used to preset the chain length. The required torque is set on the hook. Turnbuckles are available for joining two or more chains when larger items need to be secured.

Chain clamps are particularly useful for securing workpieces with complicated geometries e.g. large cast iron items. They are used during the machining of large parts, to secure heavy items for transport and for other applications. Chain clamps are very versatile clamping and securing devices that find use in many industries.

The group "chain clamp" by KIPP includes chain clamp sets, roller chains in various lengths, turnbuckles and prism halves to support the workpiece, all made from steel.