Zero-point clamping system

Zero-point clamping systems by KIPP

A zero-point clamping system is a clamping technology fixture. The concept of the zero point plays a decisive role in workpiece clamping in zero-point clamping systems.

The term 'zero point' refers to a fixed reference point from which workpieces are positioned. This zero point serves as the starting point for all further processing steps in the production process. It allows for precise and repeatable positioning of workpieces on the processing machine. This is particularly important to ensure consistent processing and high quality of the end products.

By using the zero point as a reference point, workpieces can be clamped with minimal manual intervention and without complex alignment and adjustment processes.

In recent years, this innovative technology has attracted considerable attention and has been used in a wide range of industries. The zero-point clamping system allows for workpieces to be clamped without realignment. This increases efficiency and machine utilisation, shortens setup times and as a result increases productivity.

UNILOCK clamping module - Modularity and versatility

Advantages of the UNILOCK zero-point clamping system

Application of a zero-point clamping system

UNILOCK clamping module - Modularity and versatility

There are different types of zero-point clamping systems, including the UNILOCK system, which differs in terms of functionality and possible applications.

A zero-point clamping system is made up of several components. The interaction of these components facilitates efficient workpiece clamping and machining on a CNC machine or other machining centre.

Zero-point clamping module

Clamping modules form the basis of the zero-point clamping system. They are mounted on the machine table and serve as an interface between workpiece and machine. Part of the clamping modules are chucks that allow the workpieces to be clamped quickly and securely.

The KIPP range includes seven different clamping modules. UNILOCK clamping modules enable installation with or without overhang in any position. They can be mounted on machine tables or in fixtures such as cubes, plates or towers. This makes it possible to create a customised zero point system. The modular design of the clamping system enables optimum adjustment to the clamping task. The number and spacing of the clamping modules can vary. The high clamping forces can be created by the built-in spring package.

All clamping modules of this category include a turbo function as standard. A short pulse of air at the "Turbo" air port is enough to significantly increase normal retraction force achieved by the springs. The turbo function allows clamping modules to be used for heavy-duty machining. All clamping modules are made of case-hardened steel, except for ERGO 138. Clamping module ERGO 138 is made of QT steel.

For more detailed information on both materials, please see our material overview.

Clamping station

The clamping station is a key component of the zero-point clamping system. It includes several clamping modules and serves as an interface between the zero-point mandrel and the clamping modules. The clamping station allows for precise and time-saving positioning of workpieces on the machine.

The KIPP product range includes different UNILOCK clamping stations. You can choose between the following UNILOCK clamping stations:

- 1x

- 2x

- 4x

- 6x

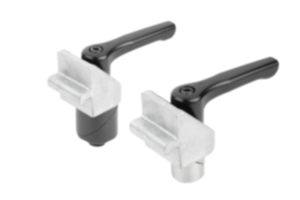

Clamping stations can be attached to the machine table using claw clamps or by screwing them directly onto the machine table. The attachment points are pre-centred and reference holes enable precise alignment of the clamping stations.

The clamping force of the clamping pins varies depending on the type of fixing screws used and is:

- M10 - 35.000 N/Module

- M12 - 50.000 N/Module

- M16 - 75.000 N/Module

In addition to these main components, zero-point clamping systems may also include other accessories and options, such as:

- Pallet couplers

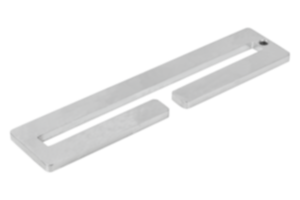

- Interchangeable subplate

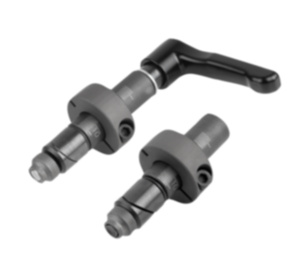

- Manual clamping module

- Clamping bolts

- Protection bolts

- Clamping bracket

However, the exact configuration of a zero-point clamping system depends on the specific requirements of the production environment and workpieces to be machined.

Advantages of the UNILOCK zero-point clamping system

The use of a UNILOCK zero-point clamping system has a number of advantages. These make clamping solutions a premium choice for companies in the manufacturing industry. We have listed the most important advantages below:

- Increased efficiency: By using UNILOCK zero-point clamping systems, you can significantly reduce your production set-up times. Workpieces can be positioned and fastened quickly and precisely on the machine, which leads to a significant increase in productivity.

- Repeat accuracy: The UNILOCK system guarantees high repeat accuracy in workpiece clamping. As a result, consistent quality of your products is ensured and waste reduced.

- Flexibility: KIPP offers a wide range of UNILOCK clamping modules, clamping stations and accessories. The versatile use allows you to customise zero-point clamping systems to your specific requirements. From machining small parts to large workpieces.

- Easy to operate: The UNILOCK zero-point clamping system is user-friendly and easy to operate. Clamping modules can be assembled and set up quickly as well as easily, which simplifies work processes and reduces training times.

- Compatibility: UNILOCK clamping modules and stations are compatible with a wide range of CNC machines and tools. This allows you to integrate zero-point clamping systems into the existing production environment without having to make any major adjustments.

Mentioned advantages are but a few of many more. Improved quality and precision in production and increase in competitiveness complete the advantages of zero-point clamping systems.

Application of a zero-point clamping system

A zero-point clamping system is typically used in the metalworking industry, particularly in areas such as CNC machining, automotive manufacturing, the aerospace industry, medical technology and electronics manufacturing. Here you can have a look at a typical application of a UNILOCK zero-point clamping system:

KIPP as an experienced manufacturer of zero-point clamping systems

KIPP, as an experienced manufacturer of zero-point clamping systems, is know for high-quality and reliable products. KIPP offers a wide range of products in the area of clamping technology.

One of KIPP's most outstanding features is the ability to offer clamping stations in made-to-measure dimensions. These customised solutions allow you to precisely adjust zero-point clamping systems to your specific needs. Be it in terms of size, capacity or other technical specifications.

By providing clamping stations in made-to-measure dimensions, we show our commitment to customised solutions and our ability to respond to individual needs. Our many years of experience and expertise make KIPP a trustworthy partner for companies that require high-precision and efficient zero-point clamping systems.