Industrial chain clamps

Chain clamps offer a reliable solution for clamping and securing workpieces with irregular contours and shapes. These clamping elements can replace costly special clamping devices, particularly in machine and plant construction. Chain clamps are used to securely hold down heavy or irregular workpieces.

The chain clamp is mounted on the machine table or a clamping plate using cap screws and T-nuts.

The even force distribution generated by the clamp ensures that the workpiece is secured without distortion. In addition to these positive features chain clamps by KIPP have further advantages:

- KIPP chain clamps have high clamping forces.

- They feature a large adjustment range.

- The workpiece is protected by plastic elements .

How chain clamps work in machine construction

Products of the chain clamp range

KIPP chain clamps - always a good choice

How chain clamps work in machine construction

The application areas for chain clamps include mechanical and plant engineering. Clamping devices can be used to securely and effectively clamp round, irregular or large to very large workpieces in the simplest and quickest way.

Chain clamps are particularly suitable for cylindrical workpieces such as valve housings, pistons and similar components. The strategic placement of plastic elements minimises the load on the workpiece, enabling gentle clamping. The chain length and tension force can be adjusted on the bracket via a knurled nut. The torque required for optimum clamping is precisely adjusted on the swing bail. This ensures flexible and precise handling .

Two things should be taken into account during installation.

- The chain angle should not be exceed 30°.

- The maximum permissible tightening torque depends on the style of the chain clamp set

The basic principle of a chain tensioner is based on the precise chain tension control in a drive system. The chain tensioners are designed to tension the roller chain tightly and thus ensure reliable and efficient power transmission.

The role of chain tensioners in the industry is diverse and crucial for the performance of drive systems. Key aspects include:

- Efficient power transmission: Chain tensioner sets ensure precise tensioning of the roller chain, which enables efficient and reliable power transmission in machines and systems.

- Reduction of slippage and vibrations: The correct tension minimises chain slippage, which leads to a reduction in vibrations and noise.

- Workpiece protection: By incorporating plastic elements into the clamping chain set, the load on the workpiece is reduced, which is particularly important when clamping irregularly shaped workpieces.

- Adaptability: The chain clamping set is often customisable and can be selected according to different chain lengths or clamping forces, providing flexibility in various industrial applications.

Products of the chain clamp range

The KIPP range combines precision, reliability and innovation. Our aim is to fulfil your requirements in respect of efficient chain guidance in mechanical and plant engineering. Our chain tensioners not only offer precise tension control,but also long service life and versatile customisation options. The product family "chain clamps" includes four different items.

- Chain clamp sets

- Roller chains

- Turnbuckles for chain clamp sets

- V-block halves for chain clamp sets

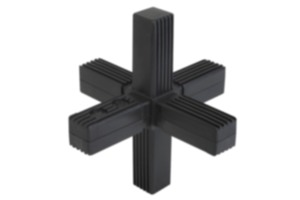

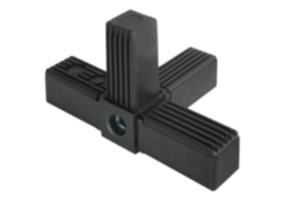

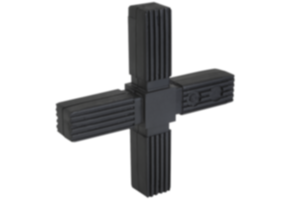

Overview of the various KIPP products

Shown below is a general overview of the four products.

Chain clamp sets

Chain clamp sets by KIPP are available in two styles. Both sets include the following items:

| |

| The difference between the two chain clamp sets lies in the length of the roller chains and therefore in the clamping force. The clamping force of the K1650.15 chain clamp set is 15 kN, the clamping force of the K1650.40 set is 40 kN. | |

Roller chains

The chain clamp sets can be expanded with separately available Roller chains . Roller chains can be shortened individually or combined with other roller chains as required. They can be used for clamping round, large or bulky workpieces. Roller chains are characterised by their low chain elongation. They are made of steel and are therefore resistant to temperature effects and dirt.

Roller chains are available for clamping forces of 15 kN and 40 kN. The chain length is customisable. The following chain lengths are available:

- 126 mm

- 148 mm

- 250 mm

- 253 mm

- 504 mm

- 507 mm

- 1012 mm

- 1015 mm

Steel turnbuckles

| Turnbuckles are typical accessories for roller chains and chain clamp sets. KIPP offers turnbuckles for tensioning chains in two sizes. They are made of high-strength steel to ensure reliable and robust tensioning. Especially with longer chains, the chain length has to be adjusted. The play is easily taken up. |

V-block halves for chain clamps

V-block halves for chain clamps are also available in two sizes. The v-blocks are required for flexible positioning on machine tables. Slot keys can be used to achieve precise alignment. The workpiece can be attached to the machine table using slot nuts.

DIN 505 T-slot nuts are typical accessories for v-blocks halves for chain clamps.

KIPP - always a good choice

Our customers not only appreciate the quality of our products, but also our reliability. KIPP stands for decades of experience in providing high-quality industrial solutions. Our products are characterised by precision and durability, making them reliable companions in a wide range of applications.

Our team with its expertise and helpfulness is there to ensure that you get the best possible solution for your individual requirements. From consultation to delivery, we endeavour to make your purchasing process as smooth as possible.

We are happy to answer any question you may have and help you choose the most suitable product.