Buffer elements

KIPP rubber buffers – Wide range available in the web shop

KIPP rubber buffers are simple and cost-effective standard elements for elastic mounting. They are suitable for compressive and shear loads. However, rubber buffers are much less durable under shear loads than under compressive loads.

Note: Tensile loads are also possible, but should really be avoided due to peak stresses on the bond and the notch sensitivity of rubber.

Buffers are mainly used as stop buffers or for vibration damping. They are ideal for isolating vibrations that result from the use of e.g. compressors, motors or aggregates. Rubber buffers are also used when mounting mechanical components and for damping moving elements. As mentioned above, rubber buffers are used as buffers and for damping vibrations and are listed under "Buffer elements" in the KIPP web shop and catalogue.

Rubber buffers, more precisely, absorb kinetic energy from components and reduce vibration loads of the system as a whole or cushion momentum of moving objects. When designing machines, the energy released by vibrations is not to be underestimated. In most cases, these vibrations result from rotation and oscillation. That is why rubber buffers are often used to cushion shocks or recurring movements by using them as end stops. A rubber buffer significantly reduces vibration amplitude. In practical applications rubber buffers are classically used as "door stops", "door buffers" and machine feet. The positive side-effect as a sound-absorbing element rounds off the portfolio.

Application areas for rubber buffers with steel and stainless steel cores

Classic application areas of rubber buffers (with electro zinc-plated core) are:

- Doors

- Gates

- Hatches

- Machines

- Plants

- Motors

- Transmissions

- and as stops in machine construction.

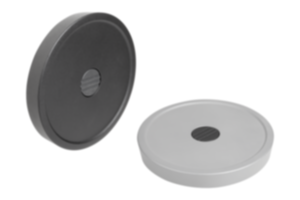

Rubber buffers in various shapes and styles

In general, rubber buffers are usually by combining elastomeric natural rubber with a steel or stainless steel core. Available are styles with internal and external threads to offer different options for installation. The KIPP range of rubber buffers is highly divers:

- Rubber buffers type A

- Rubber buffers type AT

- Rubber buffers type B

- Rubber buffers type C

- Rubber buffers type CT

- Rubber buffers type D

- Rubber buffers type DS with suction foot

- Rubber buffers type E

- Parabolic rubber buffers

- Conical rubber buffers

- Spherical rubber buffers

The many different styles (shapes) demonstrate how flexible rubber buffers can be applied. Tubber buffers absorb energy differently depending on their shape. Elements with a tapered rubber contour are ideal for high edge loads by radial deflection. Rubber buffers primarily reduce impacts. Limited availability of space is also to be considered when selecting the right buffer.

In addition to the style and material, rubber buffers are available with different thread sizes (M3/M4/M6/M10/M12/M16) and lengths. Most rubber buffers by HEINRICH KIPP WERK are available from stock in a medium rubber hardness of Shore 55 (+/- 5). If rubber buffers with other Shore hardness are required, our technical sales support team will be happy to help you find the appropriate buffer for your application. For a complete overview of the range see the KIPP rubber buffer shop online.

Information:

Rubber hardness: hard = Shore 70 medium = Shore 55 soft = Shore 45

Temperature range: -30 to +80 °C.

KIPP rubber buffers are RoHS compliant