Handwheels by KIPP

A handwheel is an operating part that helps to control mechanical systems, machines or devices. It typically consists of a radial grip attached to a shaft. The grip enables rotary movement to be transmitted to the shaft by turning the handwheel.

From manufacturing to mechanical and plant engineering, handwheels are essential components of mechanical systems that require precise and reliable operation. They are used in numerous applications and play a crucial role in a wide range of industries.

Here are some application examples...

- opening and closing valves

- manual position adjustment

- steering vehicles

- precise adjustment of machines

- adjustment of shafts, spindles and precision instruments

KIPP offers handwheels in different sizes, materials and designs. The versatility of our handwheels and the ability to offer direct manual control make them essential components in your production environment!

Features and advantages of handwheels

Handwheels for the industry

KIPP handwheels - Improve control, increase efficiency

Features and advantages of handwheels

Handwheels offer a variety of specific features and advantages. These individual aspects make them essential components in different industries and applications. Advantages of KIPP handwheels are:

- Comfortable operation: Our handwheels have been developed to fit the hand perfectly. They therefore enable comfortable gripping and turning movement.

- Durable quality: Manufactured from high-quality materials such as aluminium, thermoset, stainless steel, grey cast iron, polyamide, steel or thermoplastic, our handwheels offer long service life and reliability. Rely on a sturdy construction that can withstand even the most demanding needs.

- Versatile use: Some of our handwheels are specially designed for use in environments with high humidity or aggressive chemicals. You can rely on our products to maintain performance even under extreme conditions.

- Space-saving design: With folding grips, our handwheels are not only easy to use, but also help to save that valuable space. Maximise your working environment and use available space more efficiently thanks to our space-saving solutions.

Overall, handwheels offer a number of advantages. These make them critical components in numerous industrial environments. Due to these advantages, they improve efficiency, safety and performance of machines while ensuring comfort and user-friendliness.

Handwheels for the industry

The KIPP range includes a wide variety of different handwheels. These not only differ in size and material, but also in design. The different types of handwheels feature specific properties and are used in a wide range of applications. Please find more details on product variety below.

2-spoke handwheels

KIPP offers two types of 2-spoke handwheels. They mainly differ in material - plastic or aluminium. 2-spoke handwheels feature two radially arranged spokes that provide easy and even grip.

The production from plastic or aluminium gives the handwheels high strength and durability, while at the same time they remain light and easy to handle. This makes them perfect for applications, such as machine tools, valves, appliances and other industrial applications, where reliable manual control is needed . With their ergonomic design handwheels ensure comfortable operation, which contributes to improved efficiency and productivity.

A particular highlight: Handwheels with straight rim. Its straight rim respectively flat edge makes it perfect for use in the food industry. The smooth surface minimises contamination and is easier to clean.

Handwheel according to DIN 950

Handwheels according to DIN 950 are handwheels that comply with the specifications of the German Industrial Standard (DIN) 950. The standard stipulates dimensions, materials, tolerances and other technical requirements for handwheels to ensure quality, interoperability and safety.

Handwheels according to DIN 950 by KIPP are available in different sizes and styles. They provide reliable manual operation of mechanical systems, as a result fulfilling the requirements for precision and sturdiness in accordance with the standard specifications.

By complying with DIN 950, you can be sure that handwheels offer consistent quality and performance and are compatible with various applications.

he Kipp range includes the following handwheel according to DIN standard:

Handwheels with folding grip

This type of handwheel has a grip that can be folded. So it's not surprising that handwheels with folding grips are used in applications where space is at a premium. Handwheels with folding grips are available in different designs. For example 2-spoke handwheels and disc handwheels.

The folding grip offers a number of advantages:

- Saving space: The available space can be used more efficiently by folding down the handle.

- Safety: In circumstances where the grip might get in the way or could be operated accidentally, folding the grip down helps to prevent accidents and improve safety in the workplace.

- Easy operation: The folding grip makes it easy and convenient to operate the handwheel, as the grip can be folded in or out as needed.

Disc handwheel

A disc handwheel has a flat, disc-shaped design. Unlike traditional handwheels with a radial grip extending from a central hub point, disc handwheels are flat and have a uniform circumference. Due to its flat design, disc handwheels take up less space and are therefore perfect for applications where space is limited. Especially if the wheel is used without grip or with a folding grip. Mentioned disc handwheel made of aluminium are delivered with the hub cover not being mounted. This offers increased flexibility during assembly.

Disc handwheels are used in a variety of areas, including mechanical engineering and the automotive industry. Their space-saving design and practical functionality make them a popular choice for different applications and environments.

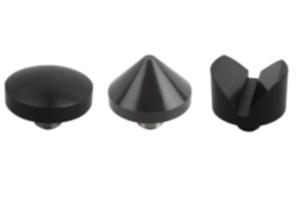

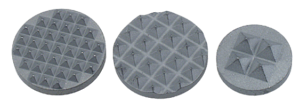

Knurled knobs

Knurled knobs are a type of handwheel with knurled surfaces. This knurling is made up of small grooves that run along the circumference of the wheel and provide a non-slip surface. The ribbed texture makes it easier to grip and turn the wheel, even in conditions where increased grip is needed. This could, for example, be the case in damp or oily environments. In addition, the surface allows the wheel to be turned quickly and precisely, resulting in improved efficiency and productivity.

Delta wheels

Delta wheels have a triangular shape, similar to the Greek letter delta (Δ). These handwheels have three evenly distributed gripping surfaces along their circumference. The surfaces allow the handwheel to be gripped and turned in different positions. This facilitates ergonomic handling, as the wheel can be gripped from different angles to achieve optimum leverage.

Delta wheels by KIPP are available in different diameters (50 mm, 63 mm and 80 mm) and colours, including colza yellow, black-grey, signal green, traffic blue and traffic red.

These colours allow individual delta wheels to be identified, making everyday work easier.

KIPP handwheels - Improve control, increase efficiency

As a manufacturer of operating parts with many years of experience and an outstanding reputation, we offer you a wide range of handwheels for your industrial applications. Our extensive product range not only includes handwheels in different sizes, materials and designs, but many other products as well.

For us quality and precision is of great importance. All products are manufactured according to strict quality standards and are subject to thorough quality control. This allows us to meet our own high standards.