Level indicators / screw plugs

Grease nipples, level indicators, screw plugs by KIPP

HEINRICH KIPP WERK offers a wide range of different operating parts. These include filler necks, level indicators, grease nipples and screw plugs. These items are grouped in the category "Level indicators, screw plugs". Discover an extensive range of different products with a multitude of options.

The grease nipple range by KIPP

Grease nipples are small standard parts that supply bearings and other moving parts with grease or other lubricants. In order to ensure reliable lubrication, the lubricant must be regularly refilled or replaced using a grease gun.

Operating principle of grease nipples

The operating principle of grease nipples is very simple. They act as nozzles so that lubricants such as grease can be applied to moving parts such as bearings by means of a grease gun. Since moving parts have a very small clearance, the lubricant must be filled into a very limited space under high pressure. Grease guns are used for this purpose. They press the grease in at a pressure of up to 400 bar.

The special shapes of the grease nipples enable the mouthpieces of the grease gun hoses to be securely fastened, ensuring safe charging with lubricants. A check valve integrated into the grease nipple ensures that the pressed-in grease does not run out again. It consists of a spring-loaded ball. During filling, the ball is pressed inwards by the pressure and allows the lubricant to flow past. After filling, the pressure drops, the spring pushes the ball upwards and thus closes the grease nipple.

Several forms - the appropriate grease nipple for every application

Grease nipples can be used for different lubrication applications in a range of locations. Different options of grease nipples are available to ensure the best possible accessibility.

Conical head grease nipples

The KIPP range includes conical head grease nipples with tapered thread acc. to DIN 71412. The name is derived from the conical shape of the nipple. Conical head grease nipples are the most commonly used type of grease nipple. They are available in various forms: · straight with a hex collar (Style A) · angled at 45° with a hex collar (Style B) · angled at 90° with a hex collar (Style C) · angled at 45° with a square body (Sytle D) · angled at 90° with a square body (Style E). Thanks to the different forms, even components in hard-to-reach places can be easily lubricated. As opposed to tapered press-in nipples or other press-in grease nipples, threaded grease nipples are also suitable for mechanically operated grease guns. As the conical head grease nipples are screwed in, they will not be pushed out even under high pressures. They have M6, M8 or M10 threads, depending on the style. Protective caps are available in various colours to protect the grease nipple heads.

Button head grease nipples

DIN 3404 button head grease nipples are also available from KIPP. The design permits a high lubricant flow rate and is therefore suitable for applications that require a lot of lubrication. They are all screw-in models and available with thread sizes M6, M8, M10, M12, and M16. Press-in grease nipples are not available. The robust design makes them ideal for machine applications where they are exposed to high external stresses.

Flush-type grease nipples

The flat design of flush type grease nipples acc. to DIN 3405 makes them suitable for recessed or flush installation. KIPP has various forms in its range: · straight with hex head (Style A) · angled at 45° with square body (Style B) · angled at 90° with square body (Style C). They are available with M6, M8 or M10 threads. The funnel shape enables reliable lubrication even in places that are difficult to access. However, care has to be taken to ensure that the grease gun is firmly connected.

Application areas of grease nipples

Grease nipples are suitable for most applications where something needs to be lubricated or supplied with lubricant. This includes not only machine and equipment construction, but also vehicle and special machine construction. The applications are not only limited to the industrial sector, they are also used in the private sector. While bearings and moving parts on machines need to be lubricated in industry, grease nipples are used in the private sector on such things as trailer overrun brakes as found on caravans.

Other products from the grease nipple, level indicator and screw plug range

Oil level gauges

Level indicators or oil level gauges by KIPP reliably indicate the fill level of tanks and other containers. Attached to the outside, the respective fill level or fill height can be easily read off. The various sizes make the indicators suitable for different types and styles of tanks: And it does not matter whether it is a tank for heating oil, hydraulic fluid or lubricant. In addition to the fill level, some variants also display the temperature of the medium in the container. Alongside the analogue versions, the KIPP range also includes electronic versions that send various information to a control unit via cable. The KIPP online shop includes

electronic oil level indicators for monitoring fill levels. There are also models that display temperature and options that display fill level and temperature.

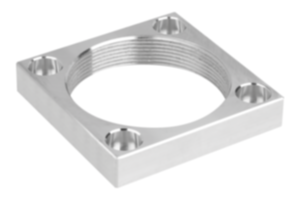

Filler neck

Containers often have a filler neck to facilitate the filling of liquids. In addition to assisting with filling, they also ensure secure closure of containers such as oil tanks, heating oil tanks, hydraulic tanks or lubricant tanks. Various models of filler necks are available. These differ in material and functionality and thus allow for use with different liquids. They are, for example, made of chrome steel or plastic and, depending on the product, feature a vent valve.

Screw plugs

Some screw plugs and press-in plugs are classic DIN parts. They are available, depending on the design, with or without a seal, and reliably plug openings. A wide product portfolio is created by using different materials such as brass, plastic, aluminum or steel. Therefore, appropriate screw plugs or press-in plugs are available for almost every application. Depending on the style, they are installed using a hex key, spanner or by hand.