Pull handles, recessed handles, ledge handles

Pull handles, recessed handles, ledge handles

Pull handles, recessed handles and ledge handles are three different types of grips and are also known as grip elements. The three handle types are used for different applications. Because every grip element has its own special features and is used for specific purposes.

The choice of the appropriate grip element depends on various factors, such as the required stability, comfort or user-friendliness. The variety of handle types enables individual requirements in different fields and sectors to be met and optimum handling to be guaranteed.

Pull handles and tubular handles from KIPP

Pull handles

Pull handles are standard parts and are characterised by their contoured form. The shape enables users to grip the handle comfortably.

Due to the unique shape and function, pull handles can be found in many fields of use. Pull handles are often used in industrial and trade applications, especially where heavy loads need to be lifted or moved. They are also widely used in everyday life. Furniture items such as wardrobes or drawers can be easily opened and closed using pull handles. They are also used in building services, e.g. on doors or windows to open and close them with ease.

A special feature of pull handles is their stability and robustness. They are often made from hard-wearing materials that enable long-term use. Pull handles are also characterised by simple design and easy installation. The ergonomic design ensures comfortable handling and minimises strain on the wrists and fingers. They enable optimum distribution of force and reduce the risk of fatigue or injury during long periods of work.

At KIPP you will find a wide selection of particularly sturdy and ergonomically shaped pull handles. Choose between different colours, shapes and materials.

Pull handle versions

With rounded edges, fold-down or customised design - the pull handles from HEINRICH KIPP WERK can be adapted in terms of form to numerous application areas and enable a secure grip. This makes them ideal as door handles, grab handles or carrying handles.

Materials used to manufacture pull and tubular handles

To cover a wide range of requirements, KIPP uses a variety of materials in the manufacture of its pull handles. From round steel with a plastic coating for better handling to lightweight aluminium and glass bead-reinforced polyamide through to a mix of materials.

KIPP offers pull handles made from the following materials:

- Aluminium

- CFK

- Thermoset

- Stainless steel

- Grey cast iron

- Polyamide

- Polyphthalamide GF50

- Polypropylene

- PVC

- Steel

- Thermoplastic

An aluminium or cast iron pull handle is inexpensive, yet robust. If you need a lightweight pull handle, we recommend the plastic ones. For hygienically demanding environments, the antibacterial thermoplastic bow handle is ideal.

Special anodising processes and coatings ensure improved surface protection - KIPP handles are thus also protected against corrosion and are therefore particularly durable.

Tubular handles

Tubular handles are cylindrical grips. They are simple and comfortable to use as they are easy to grip and hold. Tubular handles are versatile grip elements that find use in various areas. From the furniture industry to medical devices. Due to their stability and robustness, they are very popular and are often found on tools, sports equipment or transport devices.

A special feature of tubular handles is their robustness and stability. They are often made of durable materials such as metal or plastic, which guarantee long-term use.

Tubular handles are not only functional, but often also provide an aesthetic element. They are available in different colours or surface finishes to suit individual preferences and styles.

A tubular handle consists of a tube and two feet. The feet are fastened to the workpiece. The simple design of the handle tubes enables special lengths to be easily realised.

KIPP therefore already offers large hand tubular handles. The dimensions can be selected in the product overview.

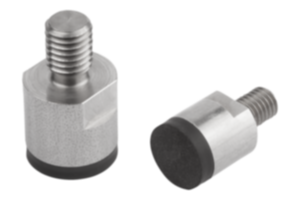

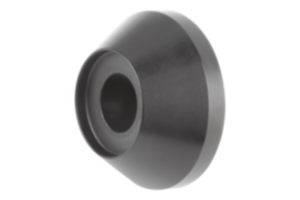

Recessed handles, recessed fold-down handles

Recessed handles have a shell-like structure that allows the user to grip them with the finger tips. These are very stable grip elements and can withstand heavy loads. They are often made from. or coated with a soft material to provide a comfortable grip. The shell-like structure conforms to the shape of the hand and enables natural and comfortable gripping.

Recessed handles are ideal for appliances and housings, but are also frequently used on everyday objects. They offer ergonomic handling and are non-slip to ensure safe use. Recessed handles often have textured surfaces or grip areas. Even if the hands are wet or oily, a secure grip can still be guaranteed. This feature makes recessed handle particularly popular in environments where safety is important.

KIPP offers recessed handles made of different materials. Depending on the area of use, one material may be more suitable than another.

The thermoplastic (ABS) recessed handles are easy to install. Die Montage erfolgt durch Eindrücken und Klemmung in die Montageöffnung. The recessed handles made from polyamide can be clipped in and are suitable for a material thickness of 0.75 mm to 3.5 mm.

The fold-down, aluminium profile recessed handles are suitable for installing in sheet metal. They can be mounted in a sheet thickness of 1 mm to 2.5 mm using 2 soft plastic profiles.

Stainless steel recessed handles have a shallow installation depth. They are ideal for floor and mounting panels. The return spring causes the handle to automatically swivel back to its original position after release.

Ledge handles

Ledge handles are another type of grip. They usually consist of a grip body with a profiled surface to improve grip. Ledge handles are made of aluminium or stainless steel. They are elongated grip shells or grip strips and the rear side is attached to a workpiece so that the grip shell faces downwards.

KIPP offers ledge handles with hole spacings of 60 mm to 560 mm in its range.

ledge handles are used in a wide range of appliances. They are used to provide the user with a secure grip and ergonomic handling. They can be found on tools, sports equipment or medical and household appliances. In industry, ledge handles are used on machine control panels, switch cabinets, control systems and other devices. They improve grip and facilitate operation in industrial environments.