Indexing plungers by KIPP

The KIPP range includes high-quality locking pins in more than 1300 different types. Due to this large range of different models, they can be utilise in multiple industrial sectors. They are found wherever moving components need to be securely fixed in a specific position.

In mechanical engineering, for example, they are used for the precise positioning of axes or slides on guide rails. Not only is the safety of the system increased, but the efficiency of the production process as well. In automotive engineering, locking pins ensure reliable locking of components during assembly.

Other possible applications for locking pins are:

- Fixture construction: Mounting devices

- Food industry: Filling systems, packaging plants

- Automotive engineering: Locking mechanism for pull-outs, latches

- Rehab: Wheelchairs

However, before we look at individual products, we would first like to answer the following questions.

What are indexing plungers?

Indexing plungers are operating parts that fix or lock moving parts in a certain position. Locking is achieved by blocking movements such as turning, swaying or shifting. These bolts also enable quick and easy adjustment of moving components. Indexing plungers are often used with spring mechanisms and manual or automatic unlocking devices. This is how operating parts allow for flexible and safe operation. |

How does an indexing plunger work?

Fixing by use of an indexing plunger is carried out as follows. By pulling on the head of the indexing plunger, the bolt retracts and the object can be adjusted. When the head is released, the bolt extends again and the part to be adjusted is locked in place.

Consequently, indexing plungers prevent a change in indexed position through lateral forces. As extending and locking is also referred to as detent, operating parts are also known as detent pins.

Indexing plungers by KIPP

What are indexing plungers?

How do indexing plungers work?

Advantages of indexing plungers by KIPP

The KIPP product group at a glance

KIPP, your trusted manufacturer when it comes to indexing plungers

Advantages of indexing plungers by KIPP

Besides the versatility of the range, indexing plungers by Kipp have even more advantages. These make indexing plungers the preferred choice for fixing and positioning in many industries.

- High quality and durability: Indexing plungers by KIPP are made of high-quality materials such as stainless steel and sturdy plastic, which makes them extremely resistant to wear, corrosion and external influences. Our material overview provides more detailed information about individual materials.

- Precise locking: The bolts allow for components to be fixed and positioned precisely, which is particularly advantageous in machines and systems where precision is required.

- Simple operation: Indexing plunger can be operated with minimal effort - either by simply pressing on them or using a smooth-running rotary mechanism. This makes handling easier and increases efficiency in the work process.

- Safe and reliable: The locking mechanism is firm and reliable, which provides additional safety and ensures stability of components, even under high loads.

- Corrosion protection: Models made of stainless steel or with special coatings offer a high level of protection against corrosion. This is particularly advantageous in damp or corrosive environments, such as outdoors or in the food industry.

- Additional safety functions: Some types are equipped with integrated safety functions such as locking mechanisms. These prevent accidental loosening of fixation and ensure even more safety. Especially in areas where operating errors have to be avoided.

- Low maintenance: Due to high-quality workmanship and corrosion resistance of the KIPP indexing plungers, they are particularly durable and require only minimum maintenance.

The KIPP product group at a glance

For the best possible use of indexing plungers, a few points should be considered. Upon selection, you should thing about use in subsequent applications. Is it for adjusting the height of a grip on a unit? Or does every millimetre count, such as when adjusting components on a machine?

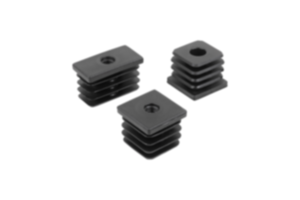

The right choice of material is important! Each material has advantages and disadvantages. Base bodies of operating elements (sleeve and bolt) are available in steel or stainless steel. This makes them suitable for various applications.

Steel models are particularly sturdy and can be used for demanding applications. If to be used outdoors, stainless steel products should be chosen. Indexing plungers made of stainless steel have got excellent corrosion resistance. Even damp or wet areas do nothing to reduce their long service life.

Almost all indexing plungers feature a plastic handle or head. It should be noted that these may only be exposed to certain temperature ranges. However, if indexing plungers are to be used in areas with higher or lower temperatures, models with a stainless steel grip have to be used.

For more detailed information and properties of the individual materials see our material overview.

In addition to the material, positioning of the bolt in use is decisive as well. The bolt should be mounted in a place that is easily accessible and offers desired stability at the same time.

Maintenance is also an issue, especially in dusty or damp environments. Bolts should be cleaned regularly and lubricated if necessary to ensure a long service life.

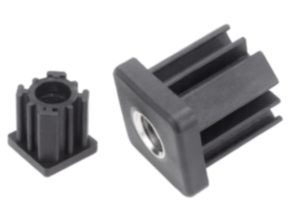

Standard indexing plunger

Types labelled as standard are indexing plungers that are operated in the classical way. The bolt is retracted by pulling on the head of the product. The bolt extends again when the head is released.

Standard indexing plungers are available with various extensions. This includes, among other things indexing plungers with detent groove. Special feature of indexing plungers with detent groove is the locking option when the bolt is retracted. If the head is pulled and turned, it remains in this position. This allows for a high degree of flexibility in use.

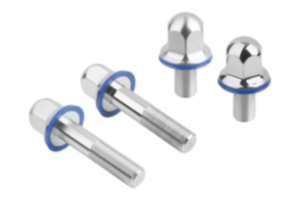

Premium indexing plungers

When selecting the right indexing plunger, it is important to know the requirements of the operating element. Besides standard indexing plungers, KIPP also offers premium indexing plungers.

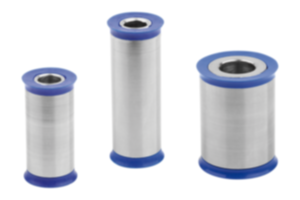

The difference here is not quality, but precision of individual operating elements. If high repeatability and fine adjustment are required, premium indexing plungers by KIPP are perfect. They are manufactured with the highest accuracy and, in combination with suitable bushings, allow for precise positioning processes.

Premium bolts are available in various shapes. It is also possible to choose the shape of the locking pin. Here we distinguish between the premium bolt with conical and premium bolt with cylindrical

Pneumatic indexing plungers

| Pneumatic indexing plungers differ from other models by the way they are operated. Such are operated by compressed air, not by hand. This allows for integration into automated production processes. The bolt is extended as soon as air is applied to the system. When the air supply is interrupted, the pin is retracted by a spring. |

Indexing plunger with in-built status sensor

Industry 4.0 is omnipresent these days and are indispensable in modern production processes. Due to indexing plungers with in-built status sensor positioning applications can now be integrated into the production process as well.

The in-built sensor sends the current status of actuation to a gateway so that it can be included in production control. This minimises errors, as a process only starts when all indexing plungers are correctly locked, for example.

Indexing plungers with lock

Indexing plungers with lock differ fundamentally from the classic type. To lock the bolt, the push button in the head is pressed. This causes the bolt to extend to the desired position and lock into place. Secure locking is indicated by a red button protruding from the side. If the push button is pressed again, the bolt unlocks. It then retracts and releases the lock. |

More customer favourites:

- Remote controlled indexing plungers are suitable for applications where the indexing plunger has to be operated remotely for safety reasons or due to a lack of space.

- In types featuring an eccentric lever, this replaces the head of the locking bolt. Due to the eccentric lever, these bolts can be opened quickly and easily with just one finger.

- Due to its versatility indexing plungers with mushroom grip made of plastic are one of our most popular indexing plungers. It is available in steel or stainless steel and also in a short design. At the same time, however, it is also available with an extended locking pin and locknut, but also without a locknut.

- The precision bolt is also part of this line. It enables high repeat accuracy to be achieved when joining two elements.

KIPP, your trusted manufacturer when it comes to indexing plungers

KIPP is your reliable partner when it comes to high-quality indexing plungers. With many years of experience and high quality standards, we provide sturdy products. You can find the right indexing for your application in our online shop.

Choose your quality product from our wide range and order conveniently online. Due to our extensive warehouse, many items are in stock, keeping delivery times to a minimum.

You can trust in our expertise and our commitment to first-class solutions!