Swivel feet, levelling feet

Levelling feet from KIPP

If unevenness in the floor or small differences in height have to be compensated for when setting up a machine or fixture, levelling feet are used. Thanks to the many different types of levelling feet, machine feet and swivel feet, almost all conceivable levelling tasks can be carried out using them. Levelling feet consist of a threaded spindle and a foot, e.g. a plate or swivel foot.

Materials – An overview of levelling foot properties

In order to enable the widest possible range of applications for KIPP levelling feet, they are offered in various materials. While the threaded spindles are generally made of steel or stainless steel, the plates are available in a variety of materials. These include steel and stainless steel, but also plastic and die-cast zinc. Some models include an anti-slip plate that absorbs vibrations and prevents the plate and therefore the entire levelling foot from slipping.

Steel levelling feet

For applications with higher loads on the levelling feet, we recommend models in which both the threaded spindle and the plate are made of steel. Material fatigue is therefore less likely and greater process reliability is thus ensured. Due to the material properties, levelling feet made of steel are primarily suitable for dry indoor areas.

Stainless steel levelling feet

Stainless steel levelling feet or threaded spindles and plates are characterised by high load capacities and great flexibility in the application sectors. The stainless steel levelling feet are just as robust as steel levelling feet, but offer additional corrosion resistance. This makes stainless steel levelling feet ideally suited for outdoor use as well as in damp indoor areas. For areas that are hygienically sensitive, KIPP offers levelling feet in Hygienic DESIGN that are especially easy to clean thoroughly.

Plastic plates

The forces acting on a plate are well distributed due to the larger surface area. The plates therefore do not necessarily need to be made of metal or steel, but can also be made of plastic. For stability reasons, by plastic levelling feet only the threaded insert is made of steel. For areas with electrostatically sensitive components, ESD plates are also available.

Die-cast zinc plates

Die-cast zinc plates are also very robust and have a degree of corrosion resistance similar to stainless steel plates. To protect the surface, die-cast zinc plates are often offered with a powder coating.

Various types of levelling feet

Standard height-adjustable levelling feet

Standard type height adjustable levelling feet are characterised by their wide range of applications. In principle, they can be used wherever a machine or device needs to be levelled up. The respective levelling feet can be individually configured to suit the requirements thanks to the many different materials and versions of the individual components.

Levelling feet with anti-slip plates

Anti-Slip plates ensure that levelling feet do not slide. The rubber pads are positioned between the floor and the plate or swivel foot and thus prevent the levelling feet from slipping. In addition, they act as vibration dampers and reduce or absorb light vibrations and movements.

Vibration dampening levelling feet

Levelling feet from KIPP are suitable for levelling up aggregates and motors. When these are running, they cause vibrations and movements that, in the long term, can damage floors and foundations. To prevent this levelling feet with vibration absorption are used. They have a rubber base that absorbs most of the vibrations and minimises their transmission to the immediate environment.

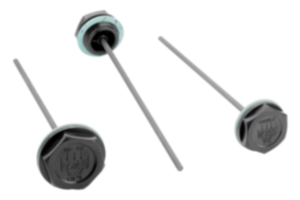

Levelling feet in Hygienic DESIGN

In hygienically sensitive areas such as the food industry, it is very important that the levelling feet can be easily cleaned and disinfected. At KIPP you will find levelling feet in Hygienic DESIGN for this type of application. These are levelling feet made of stainless steel with rubber seals, where the number of cavities and edges where dirt can get trapped has been minimised.

Levelling feet with swivel foot

Levelling feet with a swivel foot can be used on uneven or slightly sloping floors. The joint between the plate and the threaded spindle mount compensates for minor unevenness. This means that the entire surface of the plate base always rests on the floor, thus ensuring maximum stability.

Application areas of levelling feet

Due to the use of different materials and the availability of a large number of different versions, the range of applications for KIPP levelling feet is very wide. In machine and plant construction, they are used, e.g. for levelling entire production lines. In the furniture industry, they are installed on the furniture base to ensure a secure stand in later use. For measuring devices, it is important that they can be stably placed and that even minor vibrations do not affect measurement results. Vibration absorption levelling feet are often used here. But KIPP levelling feet are also used in the food industry in the form of Hygienic DESIGN products. They are easy to clean and are therefore excellent for hygienically sensitive areas.

KIPP Levelling feet – always the right choice

Discover a wide selection of different levelling feet in the KIPP online shop and find the ideal type for your application. Choose the appropriate adjustable swivel foot from many different styles. If, despite the extensive range you cannot find the perfect machine foot, then contact us. On request, we can develop an individual special solution tailored to your machine or application.