Clamping units

Clamping units by KIPP

Clamping units are devices used in the production and machining of workpieces to hold those securely in position. They are crucial for precision and quality of machining processes.

Their use not only improves quality and accuracy of machining processes, but also increases safety and efficiency in production. There are different types of clamping units, each covering specific requirements and areas of application. These include, among others:

- Thrust pads, that directly apply pressure on the workpiece

- Risers, that move workpieces into the needed position

- Riser blocks, that allow for precise adjustment of the working height

- Power clamps, that provide a strong and even clamping force

- Mechanical clamping devices - Clamp straps and claw clamps, that, due to their versatility, can be used in many areas of production

- Adjustable heel supports, that provide additional stability and support fastening of complex workpieces

What are power clamps?

Power clamps are also part of the product group of clamping devices. They are used in production technology to securely and precisely fasten workpieces during processing. A power clamp generates a strong and even clamping force that holds the workpiece in the desired position. At the same time, the clamp protects the workpiece from movements and vibrations that could impair the quality of the machining process. Power clamps are particularly important in areas where high precision and stability are needed, such as milling, turning or drilling. Their advantage is that they can be used quickly and efficiently, which reduces set-up times in production and increases productivity.

The importance of power clamps in modern manufacturing should not be underestimated. They allow for consistent quality and accuracy when processing workpieces, which is particularly important in series production. Due to the reliable clamping force even difficult to fasten or large workpieces can be held securely. This expands the range of materials that can be used and sizes of workpieces considerably.

Power clamps are used in a wide range of applications in various sectors of the industry. In the automotive industry, for example, they are used to hold car body parts in place during welding and assembly. In aerospace technology, they ensure that precision and complex components can be processed reliably. They are also essential in mechanical engineering and metalworking, as they allow for stable and precise machining of metal parts. They are also used in wood and plastics processing, where they help to hold material securely during milling, drilling or sanding.

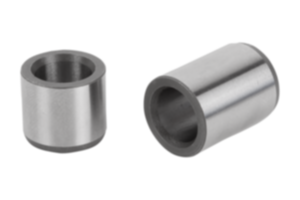

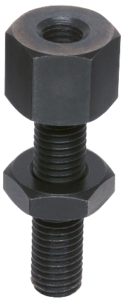

A power clamp works by exerting clamping force on the workpiece to hold it securely in the desired position. It is made up of the following components:

- Clamping body: The clamping body is the key element of the power clamp and serves as a housing for the other components. It absorbs clamping forces and ensures the structural integrity of the system.

- Clamping arm: The clamping arm is the part of the power clamp that is in direct contact with the workpiece and transfers the clamping force.

- Power source: The mechanism that generates the force required to clamp the workpiece. In case of mechanical tensioners, this can be a screw spindle or a lever.

The components work together in a coordinated process. Mechanical power clamps directly transmit the force by operation of the adjusting screw. In doing so the height of the clamping arm is infinitely adjusted and the workpiece clamped. In addition to the standard power clamp, KIPP also offers a 3-stage ratchet lever.

Advantages of power clamps

Power clamps offer a number of advantages that make them essential tools in industrial production. One of the most outstanding advantages is their very high clamping force and stability. With clamping forces between 22 kN to 49 kN, they are able to hold workpieces securely and firmly in place. The level of clamping force is particularly important when machining heavy and large parts.

Another significant advantage of power clamps is their precision and repeat accuracy. The operating elements offer a high level of repeat accuracy when positioning and clamping workpieces, which is essential for series production. Precise and consistent fastening ensures that every workpiece can be processed identically. A real advantage when it comes to maintaining tight tolerances and ensuring consistently high product quality.

Power clamps allow for workpieces to be clamped and released quickly and easily, which significantly reduces set-up times and increases productivity. This is particularly advantageous in manufacturing environments where short production cycles and high throughput rates are necessary.

Another benefit is the longevity and sturdiness of the power clamps. Power clamps by KIPP are made of QT steel for example. A material that is known for its good wear resistance, high toughness and long service life. These features ensure that the tensioners function reliably even under the most demanding conditions and offer a long service life.

Power clamps by KIPP

KIPP is one of the leading manufacturers in clamping and operating technology. We are known for high-quality and reliable products, which are used in a lot of different industries. Our power clamps stand for maximum precision and stability in workpiece clamping and are essential components of modern production.

Why buy power clamps by KIPP?

Our power clamps offer an impressive clamping force between 22 kN and 49 kN, making them perfect for securely fastening even the heaviest workpieces. They guarantee high repeat accuracy when clamping workpieces. Power clamps by KIPP are made of QT steel. This makes power clamps reliable in daily use and a sustained investment in the quality of your production.

See the quality of our products for yourself and get in touch. Our team of experts will be happy to provide you with comprehensive advice and find the best solutions for your requirements.