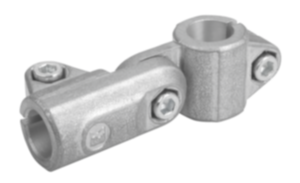

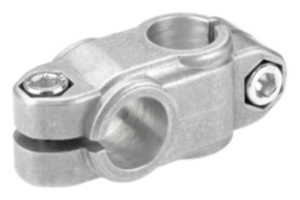

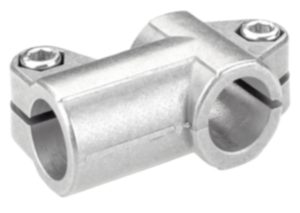

Clamping elements

Clamping elements by KIPP

The product group "clamping elements" by KIPP is divided into twelve categories:

- Clamping units

- Clamp straps

- Swing bails

- Swing clamps

- Pull clamps, thrust clamps

- Side clamps

- Toe clamps

- Fixture clamps, cam clamps

- T-slot clamps

- Wedge clamps

- Centring clamps

- Clamping elements for grid systems

Clamping elements are mainly used in fixture construction and machine tool construction for machine tools. They are components that are used to hold parts for machining, especially clamping workpieces in fixtures. They are generally used on machines and plants to clamp workpieces

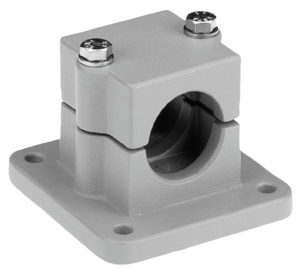

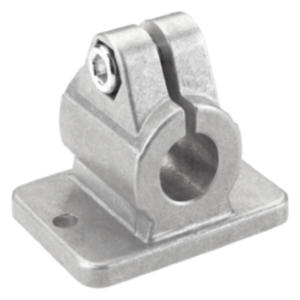

Clamping units

Clamping units are used for holding, positioning, retaining and mechanical clamping workpieces. They are generally used in workshops, plants and other industrial facilities. Combined with riser blocks and fastening elements, clamping units form a clamping assembly.

The KIPP range includes the following clamping units and a number of accessories:

- riser blocks

- clamp straps

- adjustable heel supports for clamp straps

- claw clamps

- risers and thrust pads for power clamps

Clamp straps

A clamp strap is used to hold down workpieces. Claw clamps and clamp straps are part of the group "mechanical clamping elements". Clamping straps are often used in carpentry, metalworking and other trades. They can be used to secure workpieces onto machines or workbenches.

Clamp straps can be quickly and easily adjusted to any workpiece, the simple adjustment and adaptability is a great advantage in everyday use.

Clamp straps are normally mounted with a vice or chock clamp. Then the toe presses down on the workpiece to clamp it. This enables the material to be held in position while machining or cutting it.

The KIPP range includes clamp straps made of aluminium, steel and high-carbon steel.

Hook clamps

Hook clamps are hook shaped clamps used to clamp workpieces on machines. They are frequently used in industry and trade.

Hook clamps are predominantly used where a workpiece has to be quickly and repeatedly clamped and unclamped. They can also be used to suspend loads or to attach objects to walls or ceilings. To use hook clamps, they must be attached to the respective surface. This can be done using screws, nails or other methods. Ropes, cables or chains can then be pulled through the opening of the hook clamp and fastened.

When used with a hook clamp holder or riser cylinder they can be adjusted to almost any required height.

Swing clamps

Swing clamps are mechanical devices used to secure a component in a certain position. They are often used on machines and plants to hold parts or components in place.

Swing clamps ensure rigid clamping. They can also be used as mechanical levers or supports to carry loads.

To use the swing clamp, one end is attached to a rigid surface and the other to the object to be held. The swing clamp can then be moved into the desired position by turning the lever or the rod. Some swing clamps also feature a locking function that allows them to be locked in the desired position.

Pull clamps, thrust clamps

Pull and thrust clamps are part of "mechanical clamping elements". Both type of clamp are workshop standard clamps. Due to the many different types, pull and thrust clamps can be use in many branches.

Pull clamps are used to clamp fixtures or workpieces. A pull clamp is ideal if there is little lateral space available during installation. In this case support bracket of the pull clamp are attached to the appropriate support plate from below.

Thrust clamps are mechanical devices that are used to exert a constant force on an element. They are used in many applications, for example in the automotive industry to regulate the force exerted on components such as brake pads and springs. They are also used on machines to regulate pressure exerted on certain parts or components. Thrust clamps are usually adjusted by rotating a lever or knob on the device. Some pressure clamps are equipped with sensors and other electronic components to measure the pressure more accurately. The pressure can then be read off via a scale on the side of the clamp or via a digital display.

Side clamps

Side clamps are used for clamping workpieces. As the name suggests, they clamp the workpiece on the sides leaving the top free for machining. Many of them also have a draw-down effect.

The side clamp is used together with a separate fixed jaw. Together they produce the draw-down effect forcing the workpiece down onto a rest or seating ledge. This effect ensures that the workpiece does not lift up during machining.

Toe clamps

Toe clamps are used for clamping workpieces in machines. The workpiece is clamped from the side on the lower part. These clamps can exert high forces ensuring the workpiece is securely held. The flat design enables tool access to much of the workpiece.

Toe clamps by KIPP are made of high-carbon steel. The products therefore have high degree of strength and toughness.

In addition to toe clamps, this group also includes flat clamps,toe stops, and rack plates.

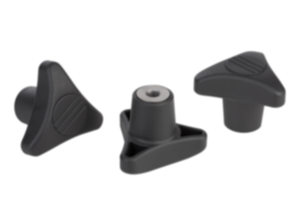

Fixture clamps, cam clamps

Cam clamps are universally applicable tools. They are particularly suitable for torque-free clamping of a thread. The cam lever converts rotary movement into linear movement. Cam clamps are therefore used in machines in which a rotary movement must be generated, a high clamping force is required or secure clamping is necessary for large adjustment ranges. Fixture clamps are self-locking and have a unique clamping lever ratio before reaching the clamping point.

The fixture clamp and cam clamp product family includes:

T-slot clamps

T-slot clamps enable clamping of very low workpieces. They are part of the product group "side clamps". Some have a draw-down effect which forces the workpiece down onto a rest or seating ledge.

To use T-slot clamps, the following steps must be carried out:

- Insert the T-slot clamp into the T-slot of a machine table. Slide the T-slot clamp up to the workpiece.

- Tighten the fastening screws of the T-slot clamp. Pay attention to the torque.

- Now clamp the workpiece by tightening the clamping screw

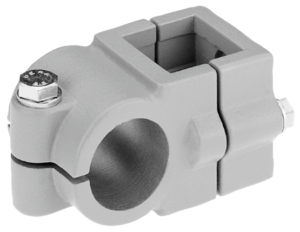

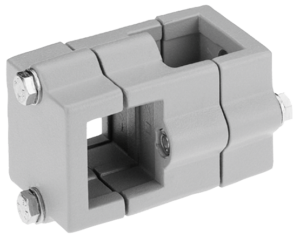

Wedge clamps

A wedge clamp can hold two workpieces simultaneously. This is referred to as multi-clamping. Wedge clamps can be used for clamping round and rectangular parts. Design and operating principle of wedge clamps enables space-saving multi-clamping.

This is why wedge clamps are usually used for multi-clamping. The downwards force of a screw is transferred to wedges and then the workpiece. The wedge faces of the wedge clamp can achieve high clamping forces. Accessories are available for some wedge clamps to achieve various clamping effects such as the pull-down effect. These accessories include socket head screws or countersunk screw.

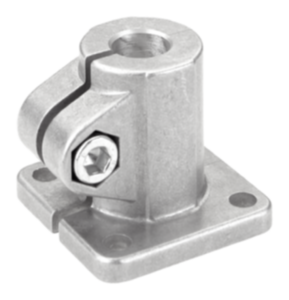

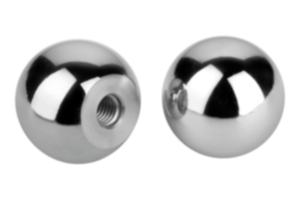

Centring clamps

A centring clamp is a machine vice and is often used in machining technology. They enable a workpiece to be centred and clamped in the bore. The centring clamp is used during machining to hold the workpiece securely.

Centring clamps have a number of jaws arranged around the circumference. The jaws all move outwards simultaneously, centring a workpiece on a bore and holding it there.

Centring clamps can be mounted directly on a machine table or a grid plate.

In addition to classic centring clamp, KIPP also offers round centring clamps with smooth jaws and those with balls or hexagons as holding devices.

Some round centring clamps have a pull-down effect. They are operated using cap screws or countersunk screws.

Centring clamps with ball or hexagonal segments have the following advantages:

- distortion-free clamping

- precise self-centring

- low overall height

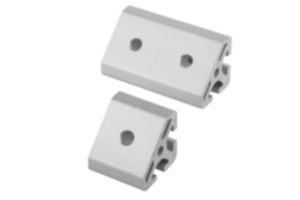

Clamping elements for grid systems

Part of Clamping elements for grid systems are the following products:

- Steel clamping pins

- Steel or stainless steel clamping pins with washer, clamping angle or adapter plate

- pivot bearings with threaded pin

- Steel plates

- Steel angles